Two stage fuel burner

TL/2 series

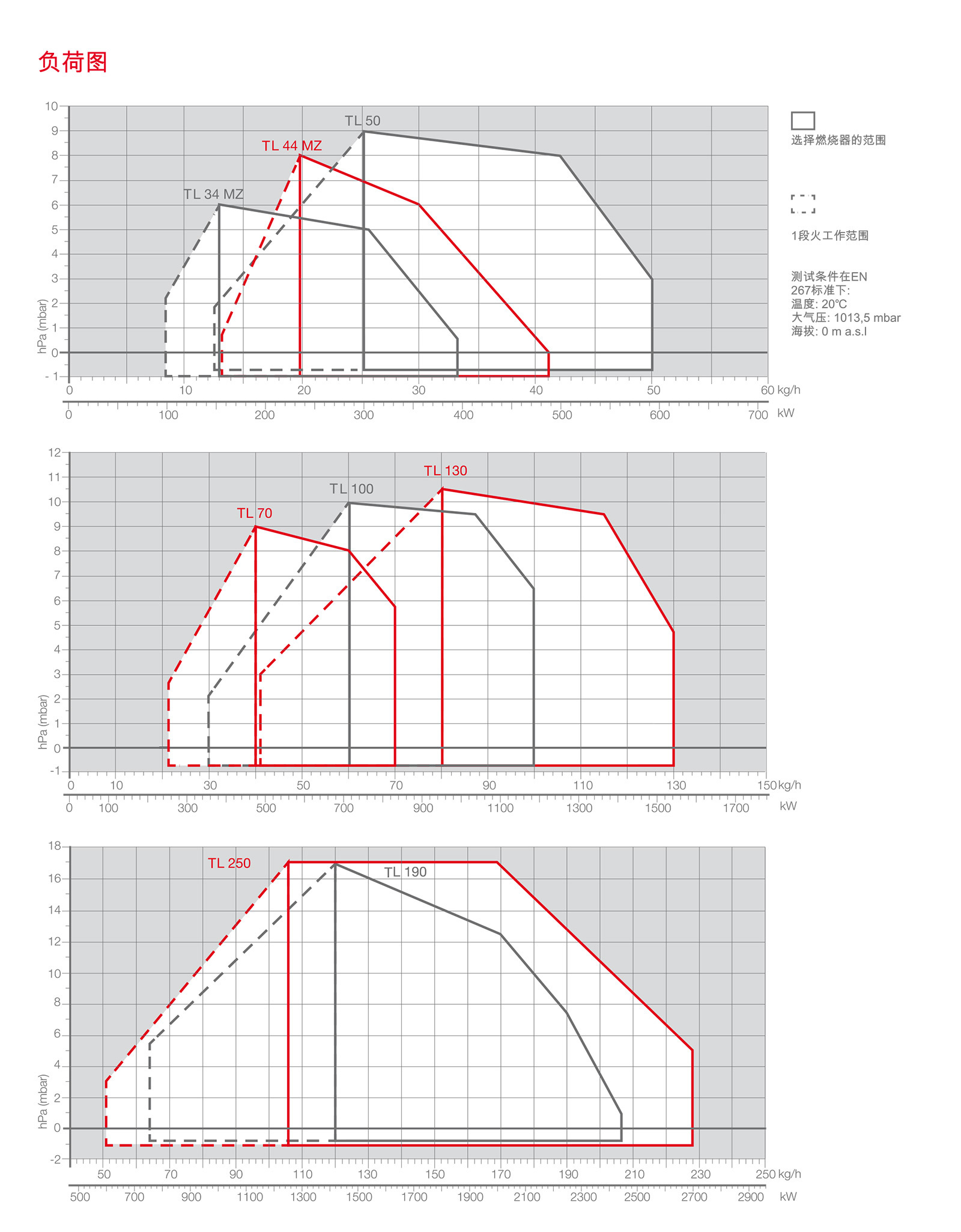

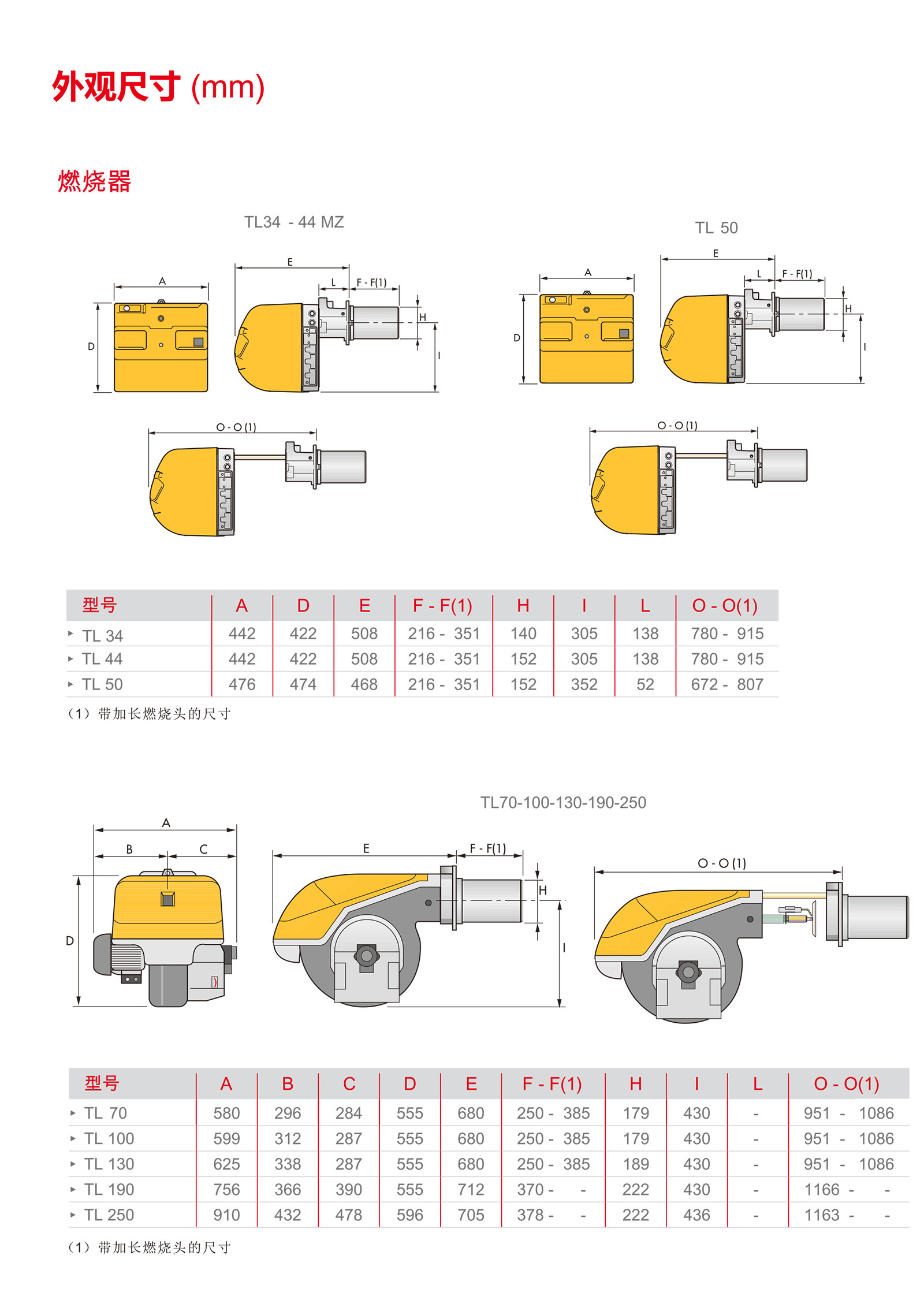

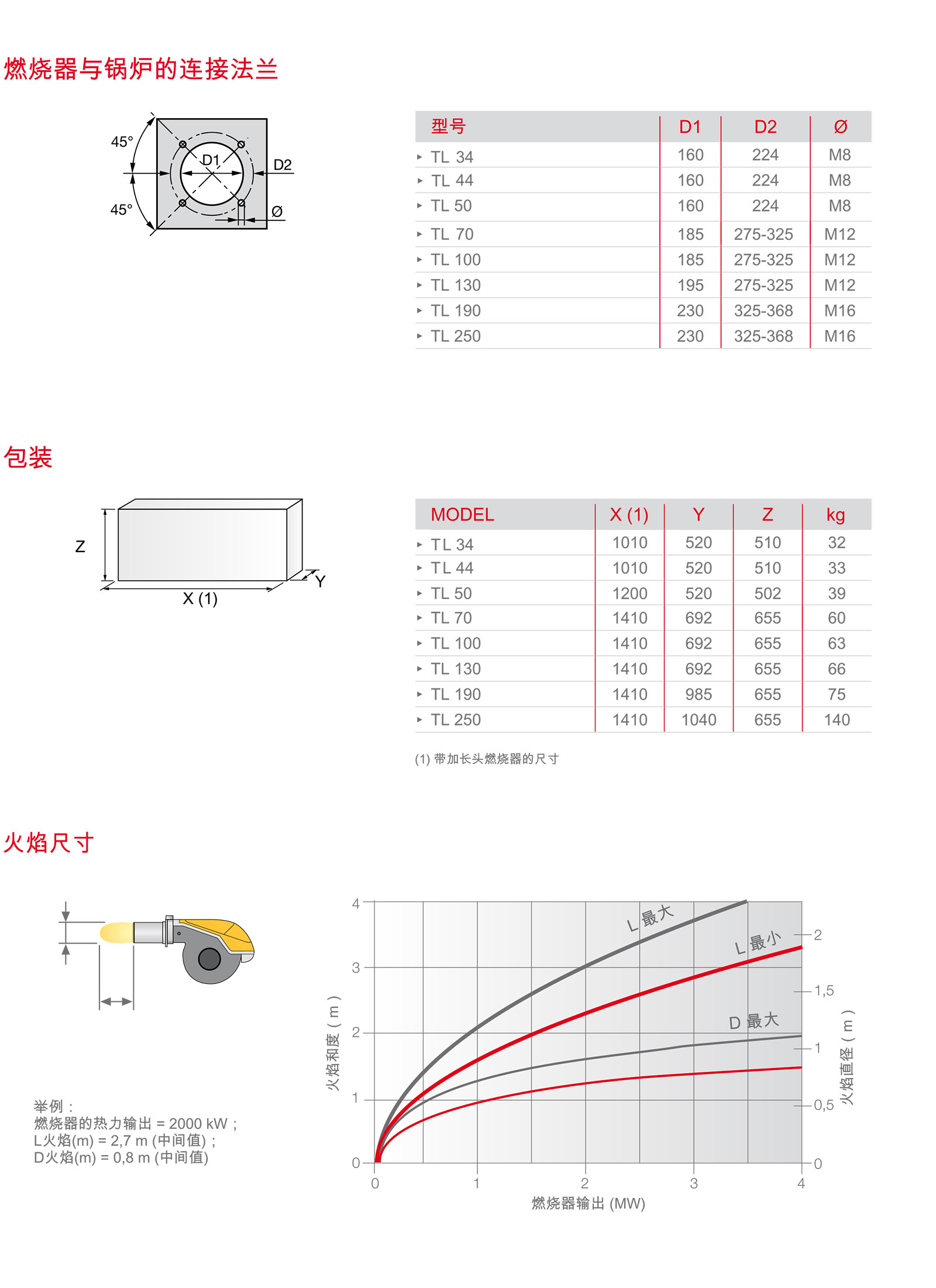

The output range of TL series burners is 154 to 2700 kW, suitable for various low and medium temperature hot water boilers, hot air and steam generators, and heat transfer oil furnaces. All models are suitable for burning light oil and biodiesel blends with a light oil and biodiesel content of not more than 5%. The adjustment method is "two-stage fire"; the burner is equipped with a microelectronic control box, which can provide the operating status and fault feedback information of the burner. The specially designed air supply system ensures that the operating noise of the burner is kept to a minimum. Improvements in fan performance and combustion head guarantee flexibility of use and optimum operation in the work area. Some advanced designs of the burner make the burner smaller and more convenient to use and maintain. Additional options ensure that the burner's functionality can be upgraded at any time.

Hotline:

Category:

Keywords:

Two stage fuel burner

Related products

FEEDBACK

Follow Us

Quanzhou tenghao automation equipment Co., Ltd

Tel: +86 595 22781716 +86 400-0808-139

E-mail: th@dowsonburners.com

WhatsApp:+86 18259706016

WeChat:+86 18259706016

Website: www.dowsonburners.com

Address: Plant 2, boutique Park, Huinan Industrial Zone, Taiwan investment zone, Quanzhou, Fujian, China

copyright © 2022 Quanzhou tenghao automation equipment Co., Ltd

-

Hotline

-

Tel:

-

Follow us

Scan QR code.

- TOP